Why Understanding Natural Gas Hookup Costs Matters for Your Budget

Natural gas hookup cost varies widely depending on your specific situation, but most homeowners can expect to pay between $272 and $936 for a typical installation. However, costs can range from as low as $120 for a simple appliance connection to over $2,000 for complex installations requiring extensive trenching or new meter installation.

Quick Cost Overview:

- Average total cost: $540-$598

- Cost per linear foot: $15-$25

- Simple appliance hookup: $120-$300

- New line from street: $500-$2,000+

- Permits and inspections: $100-$300

- Labor rates: $45-$200 per hour

Natural gas offers significant long-term savings for manufactured home owners. Gas appliances provide 100% efficiency for heating compared to just 25% for electric heating systems. Gas dryers are more efficient than electric models, and cooking with gas gives you instant temperature control that electric ranges simply can’t match.

The upfront natural gas hookup cost might seem substantial, especially when you’re already stretching your budget for a new home. But understanding these costs helps you plan effectively and avoid surprise expenses during your home setup process.

This guide breaks down every component of gas line installation costs – from materials and labor to permits and trenching. We’ll show you where you can save money and where you shouldn’t cut corners for safety reasons.

Understanding the Average Natural Gas Hookup Cost

Let’s get straight to the numbers that matter most to your budget. The natural gas hookup cost for most homeowners falls somewhere between $272 and $936, with the sweet spot around $598. But here’s the thing – your actual cost could be as low as $120 if you’re just connecting a single appliance to an existing line, or it might climb past $2,000 if you’re starting from scratch with a complex installation.

The magic number you’ll hear contractors throw around is $15 to $25 per linear foot. This is your baseline for planning purposes. If your new manufactured home needs a gas line that runs 50 feet from the street, you’re looking at roughly $750 to $1,250 just for the piping work – before you add in permits, inspections, and any tricky obstacles.

Recent data from April 2024 shows that gas line installation projects typically start at $749 to $917 per piping run. In places like Rochester, NY, the complete installation (materials plus labor) averages between $17.28 and $31.76 per linear foot. These regional variations remind us that location plays a big role in your final bill.

Project complexity makes all the difference. Think of it this way: connecting your new gas range to a stub-out that’s already waiting in your kitchen wall is like plugging in a lamp. Running a brand-new line from the street to your manufactured home? That’s more like rewiring your entire house – it involves trenching, permits, inspections, and potentially navigating around driveways, landscaping, and underground utilities.

Here’s how the costs typically break down:

| Project Type | Typical Cost Range | What’s Involved |

|---|---|---|

| Simple Appliance Hookup | $120 – $300 | Connecting to existing, accessible gas line |

| New Line from Street to Home | $500 – $2,000+ | Full installation including trenching, permits, and inspections |

The bottom line? A simple hookup might cost you less than a nice dinner out, while a complete new installation could rival a vacation budget. Understanding where your project falls on this spectrum helps you plan realistically and avoid sticker shock when the quotes start rolling in.

Key Factors That Influence Your Installation Price

Your natural gas hookup cost is a sum of several parts. Understanding each component helps you budget effectively and avoid surprises.

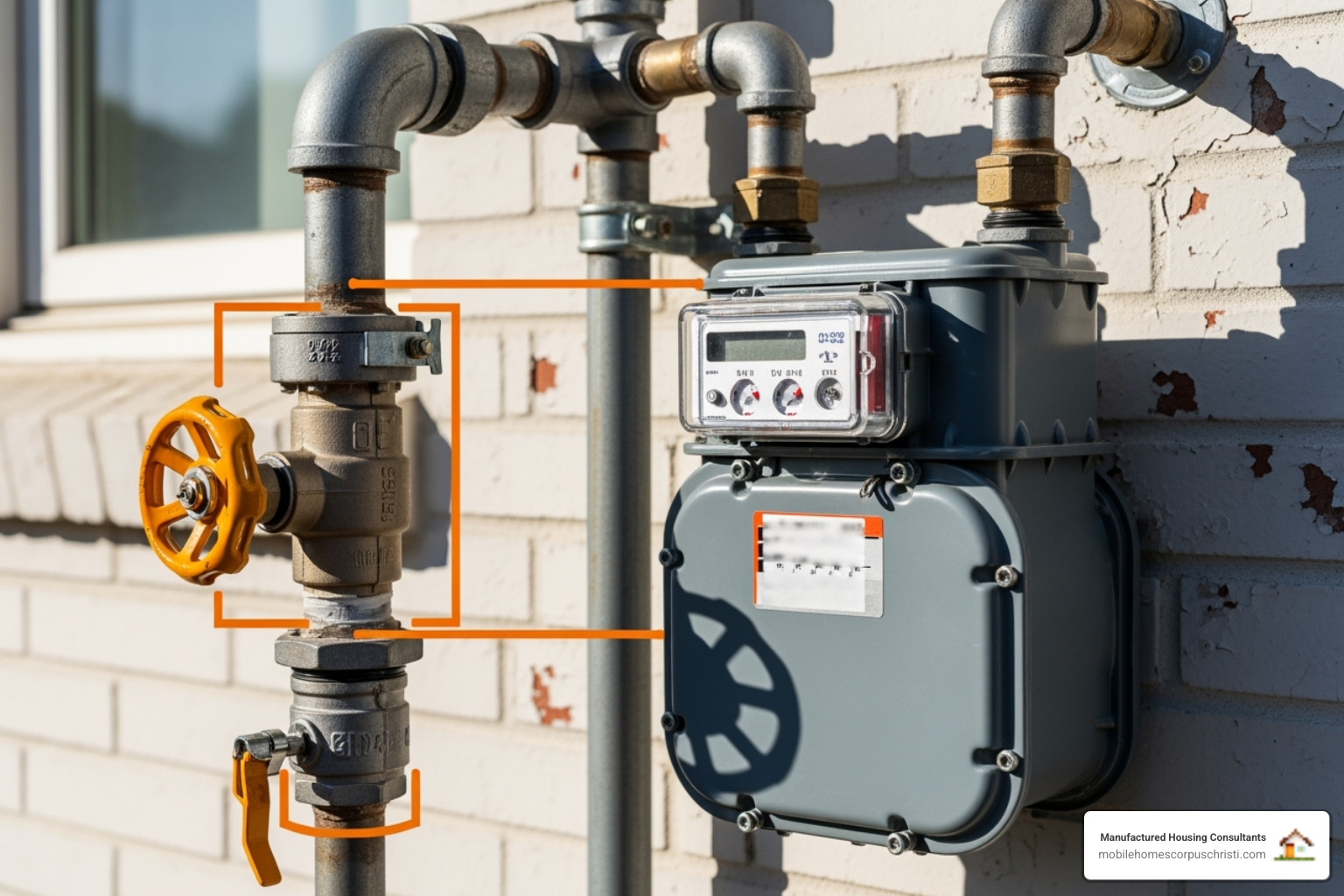

Labor Rates and Professional Fees

Gas line installation is not a DIY project and requires a licensed professional. Plumbers and gas fitters typically charge between $45 and $200 per hour, depending on their experience level. While hiring a master plumber costs more, their expertise is essential for safety and ensuring the job is done correctly and to code. Avoid emergency service calls on evenings or weekends, as rates can be 1.5 to 3 times higher. Planning ahead is key to managing labor costs.

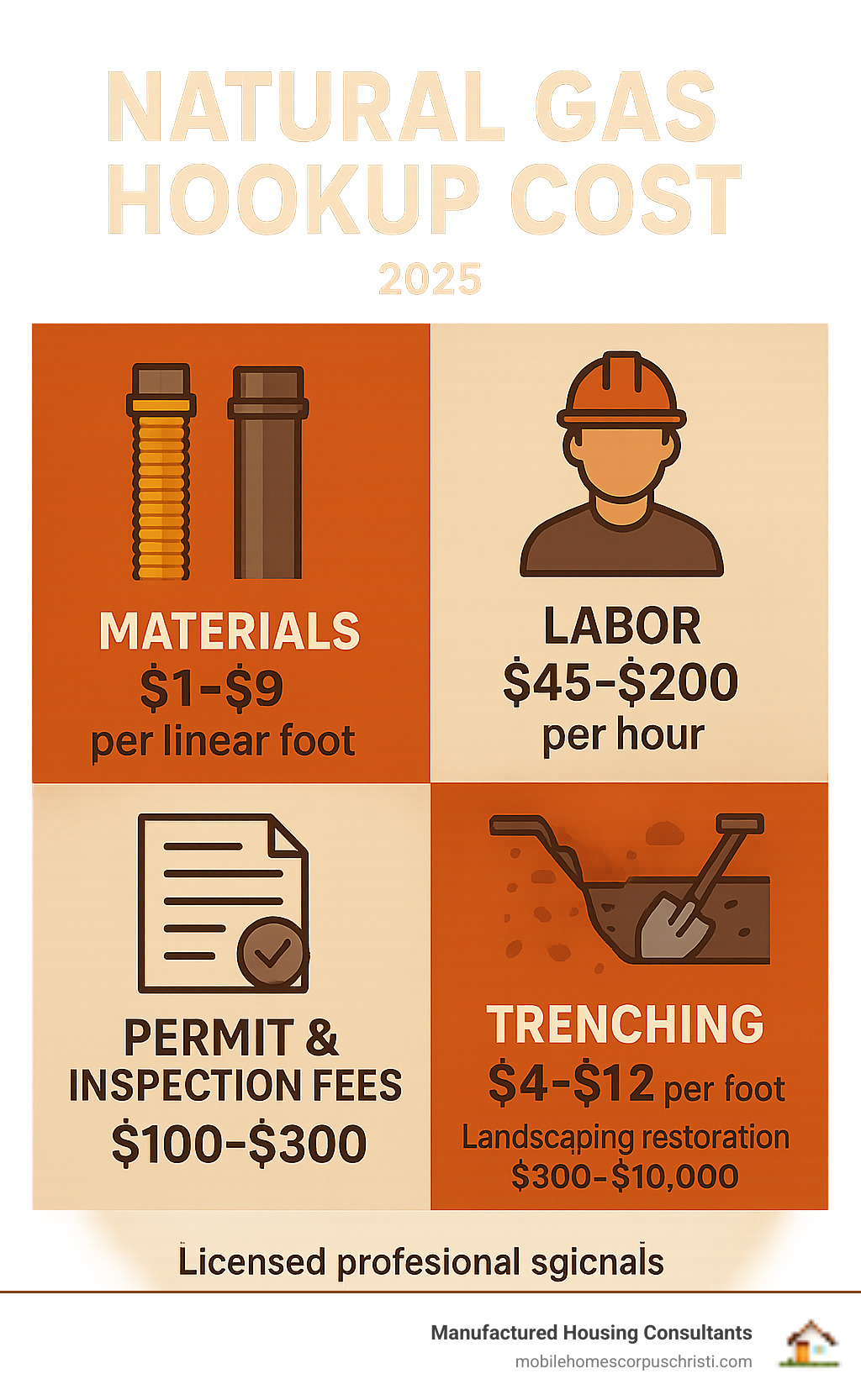

Pipe Material Costs

The pipe material affects your total natural gas hookup cost, with prices ranging from $1 to $9 per linear foot. Common options include:

- Black iron pipe: Durable and standard for above-ground use.

- Corrugated stainless steel tubing (CSST): Flexible, reducing labor time in tight spaces.

- Copper tubing: Good for smaller lines and corrosion-resistant.

- High-density polyethylene (HDPE): The top choice for underground runs due to its corrosion resistance and flexibility.

Your contractor will select the appropriate material based on local codes, application, and budget. You can browse plumbing supplies at Lowes to see these options.

Project Scope and Complexity

Costs vary significantly with project scope. A simple appliance hookup is minor, but a new line from the street is a major project. The distance from the main gas line is the biggest cost driver, as every foot adds material and labor costs. Trenching can be expensive, especially in rocky soil or complex landscapes. Urban installations often require boring under pavement, which costs more than simple trenching common in rural areas. Penetrating walls or foundations also adds to the cost.

Permits, Inspections, and Additional Fees

Permits and inspections are mandatory for safety and typically cost $100 to $300. After installation, a required pressure test to check for leaks costs $75 to $150 or more. If your utility doesn’t cover it, a new gas meter installation can add $300 to $600 to your bill. Always check with your utility provider about their policies. Your contractor will handle the permit process and be aware of any other local fees.

Trenching and Landscaping Restoration

Digging for underground lines incurs costs beyond the trench itself. Trenching costs average $4 to $12 per linear foot. Afterward, you must budget for restoration. Landscaping restoration can range from $300 for simple reseeding to over $10,000 for complex yards. Repairing driveways, patios, or interior drywall will also add to the final cost. Concrete repairs run about $75 to $125 per cubic yard, while drywall repair can cost $300 to $925. Be sure to factor these often-overlooked expenses into your initial budget.

Cost Breakdown by Appliance and Project Type

Understanding the natural gas hookup cost for different appliances and project types helps you prioritize your installations and budget accordingly.

The natural gas hookup cost for Common Appliances

The cost to connect appliances depends on the distance from the main gas line. Most installations follow a per-foot pricing model.

- Kitchen Stove/Range: A common first connection, averaging around $600 for a typical installation based on a $20 per linear foot rate.

- Gas Dryer/Water Heater: Also priced around $20 per foot, these appliances offer efficiency and performance benefits over electric models.

- Furnace/Pool Heater: Connections for these high-demand appliances also run about $20 per linear foot.

- Outdoor BBQ/Fire Pit: These popular additions typically cost $20 to $25 per foot and eliminate the need for propane tanks or firewood.

New Installation vs. Repairing or Moving a Gas Line

The type of work significantly impacts the cost.

- New Line Installation/Moving a Line: Expect to pay $15 to $25 per linear foot for a new line or to relocate an existing one, as the work is very similar.

- Gas Line Repair: Costs vary by location and severity. A minor, accessible leak might cost $120 to $250. A hidden leak in a wall could be $270 to $760. The most expensive repairs involve excavation for buried lines, running $1,500 to $5,000+.

- Capping a Line: Simply capping an unused line is the most affordable option at $75 to $150.

If you smell gas, leave the area and call your utility’s emergency number immediately. Safety is the top priority.

The Bigger Picture: Propane, Electric, and Policy Changes

When considering your natural gas hookup cost, it’s helpful to compare it to other energy options and understand how policies can affect your expenses.

Natural Gas vs. Propane Installation Costs

Propane requires on-site storage. Buying and installing a propane tank costs between $400 and $2,800, while leasing a tank runs $50 to $200 per year plus a hookup fee. While the initial natural gas hookup cost can be higher if a new line is needed, the fuel is delivered directly and is often cheaper and more price-stable than propane, leading to long-term savings.

Long-Term Savings: Switching from Electric to Natural Gas

Switching from electric to natural gas appliances often pays for itself over time. Natural gas heating is nearly 100% efficient, compared to about 25% for electric heating by the time it reaches your home. Gas appliances like ranges and dryers also offer superior performance and lower operating costs. This initial investment can lead to a significant drop in monthly utility bills. For more on energy savings, see the U.S. Department of Energy’s guide on water heating.

If you’re exploring financing for a new manufactured home and want to include utility upgrades, we can help you understand your manufactured home financing options.

How Utility Policies Can Affect Your natural gas hookup cost

Utility policies can dramatically impact connection costs. For example, New York recently ended its “100-foot rule,” which had the utility company cover connection costs for homes near an existing gas line. Now, new customers in New York must pay the full natural gas hookup cost, which can range from $2,500 to over $10,000.

Supporters of this change argue it’s unfair for existing customers to subsidize new ones. Opponents worry about housing affordability, as these high upfront costs can be a burden for new homeowners. While this specific policy is in New York, it highlights how local regulations can affect your budget. It’s always wise to understand the rules in your area before making energy decisions.

How to Budget and Save on Your Gas Line Installation

Smart planning can make a real difference when it comes to managing your natural gas hookup cost. Nobody likes surprise expenses, especially when you’re already investing in a new manufactured home. The good news? There are several proven strategies to keep your gas line installation within budget.

Getting multiple bids is your first and most powerful move. We can’t stress this enough – reach out to at least three licensed and insured professionals for quotes. You’ll be amazed at how much pricing can vary between contractors. Don’t just focus on the bottom line number though. Look at what each contractor includes in their estimate, their timeline, and their approach to the work.

Think about bundling your gas line installation with other plumbing projects if you have them planned. Maybe you need a water line run to your new manufactured home, or perhaps there’s other utility work happening. Many contractors offer better rates when they can tackle multiple jobs at once. It saves them time on setup and travel, and those savings often get passed along to you.

Your local gas utility company might have some pleasant surprises waiting for you. Check for utility company rebates or special programs for new connections. Some utilities offer financing options or even partial reimbursements for converting from electric to gas appliances. A quick phone call to their customer service department could save you hundreds of dollars.

When discussing materials with your contractor, ask about cost-effective options that still meet safety standards. For buried lines, materials like HDPE might offer better value than traditional options while providing excellent corrosion resistance. For interior runs, CSST (corrugated stainless steel tubing) can sometimes reduce labor costs because it’s easier to route through tight spaces.

Planning ahead is perhaps your best money-saving strategy. Rush jobs and emergency installations come with premium pricing – sometimes double or triple the normal rates. The entire process from permits to final inspection can take 6-12 weeks, so start early. This gives you time to shop around, compare options, and schedule work during regular business hours when rates are lowest.

For comprehensive guidance on managing all aspects of your new home budget, including utility connections, check out our guide on how to budget for your new manufactured home. Planning ahead now means fewer financial surprises later – and more money in your pocket for the fun stuff, like that new gas grill for your backyard!

Frequently Asked Questions about Natural Gas Hookups

When it comes to natural gas hookup cost and installation, we get the same questions from homeowners over and over again. Let’s tackle the big three that keep people up at night.

Who should I hire to install a gas line?

This is absolutely not a DIY project – and we can’t stress this enough! Always hire a licensed and insured plumber or qualified gas fitter for any gas line work. These professionals understand local building codes inside and out, can pull the necessary permits on your behalf, and most importantly, they know how to keep you and your family safe.

Most cities won’t even issue a permit unless a licensed professional is doing the work. This requirement exists to protect you from unsafe installations that could lead to dangerous gas leaks. While you might find a general plumber who can handle small repairs for less money, full gas line installations are complex projects that justify the extra cost of hiring a specialist.

The bottom line? This is definitely not the time for a “hold my beer” moment. Gas leaks can be deadly, and proper installation requires specialized knowledge and experience that only comes with professional training and licensing.

Do I need a permit to run a gas line?

Yes, absolutely! In virtually every jurisdiction across the country, you’ll need a permit for new gas line installations or any significant modifications to existing lines. This isn’t just bureaucratic red tape – it’s a crucial safety measure that protects your home and family.

The permit process ensures that your installation gets inspected for compliance with strict safety codes. These codes exist for good reason, as they help eliminate the risk of gas leaks that could lead to fires, explosions, or carbon monoxide poisoning.

Here’s the good news: your licensed contractor typically handles securing and managing these permits for you. They know exactly what paperwork is needed, when inspections need to happen, and how to ensure everything meets local regulations. This takes the hassle off your shoulders while guaranteeing that your gas line installation is both safe and compliant.

How long does a typical gas line installation take?

The timeline for gas line installation varies dramatically based on what you’re having done. A simple appliance hookup to an existing line might only take a few hours – pretty straightforward if everything’s already in place.

But if you’re installing a new line from the street to your manufactured home, buckle up for a longer process. The entire project can take several weeks from start to finish. Here’s why: first, you need permit approval, which can take time depending on your local building department’s workload. Then there’s scheduling with the utility company, which operates on their own timeline.

The actual trenching and installation work might take anywhere from a few days to a couple of weeks, depending on the distance, terrain, and any obstacles like driveways or existing utilities. Finally, there’s the inspection process to ensure everything meets code before your gas can be turned on.

For longer runs or installations requiring extensive digging, plan for the upper end of this timeline. Always ask your contractor for a realistic schedule during the quoting process – and remember, weather delays can sometimes extend the timeline even further. Planning ahead helps you avoid any surprises and ensures your new manufactured home is ready when you need it to be.

Conclusion

Planning for your natural gas hookup cost doesn’t have to feel overwhelming when you know what to expect. Throughout this guide, we’ve walked through the key factors that shape your final bill – from the $15 to $25 per linear foot for basic installation to the additional expenses like permits, trenching, and professional labor that can push your total investment anywhere from $272 to well over $2,000.

The most important takeaway? Professional installation is absolutely non-negotiable for safety. Gas lines carry serious risks, and this is one area where cutting corners simply isn’t worth it. The peace of mind that comes from knowing your family’s safety is protected by licensed, insured professionals is invaluable.

While the upfront natural gas hookup cost might seem steep, you’re investing in long-term savings and convenience. Gas appliances offer better efficiency, lower operating costs, and that instant control every home cook dreams of. Plus, you’ll never run out of propane in the middle of grilling burgers for a backyard barbecue again!

For homeowners in Texas, especially those considering a new manufactured home, understanding these costs is a key part of the site preparation process. Getting your utilities right from the start saves headaches and money down the road.

Our team at Manufactured Housing Consultants can guide you through all aspects of utility connections to ensure your new home is set up safely and efficiently. We understand that every detail matters when you’re making such an important investment, and we’re here to help make the process as smooth as possible. After all, your new home should be a place of comfort and joy, not stress and surprise expenses.