Why Natural Gas Hookup is the Smart Choice for Your Home

A natural gas hookup connects your home to the main distribution system, providing clean and reliable energy for heating, cooking, and hot water. It’s often a more affordable option than electricity or propane.

Key Natural Gas Hookup Essentials:

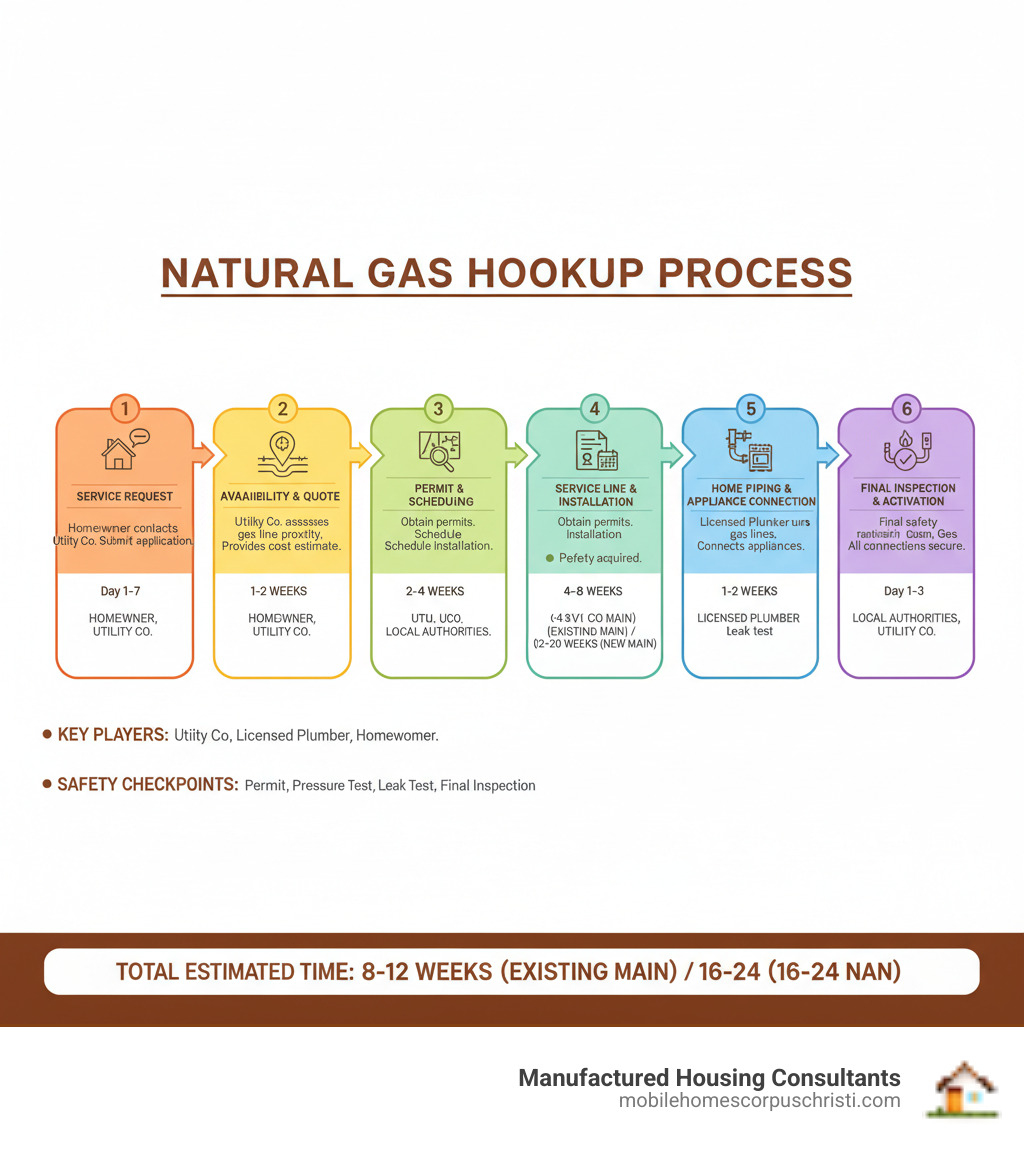

- Who’s involved: Utility company installs the service line and meter; a licensed plumber connects appliances.

- Timeline: 8-12 weeks if gas is available on your street; 16-24 weeks if a new main line is needed.

- Cost factors: Distance from the gas main, appliance conversions, and permit fees.

- Safety requirement: Professional installation is mandatory—never DIY gas connections.

- Planning needs: Check gas availability, calculate BTU requirements, and obtain permits.

Natural gas is a cornerstone of modern energy, offering homeowners significant savings—often 30-50% less than electric heating costs. For families, especially those in manufactured homes, a natural gas hookup means smart long-term savings that quickly offset the initial investment.

This guide covers everything from planning and utility coordination to the installation process, including special considerations for manufactured homes, safety rules, and typical costs, so you can make an informed decision.

Before You Begin: Planning Your Natural Gas Hookup

A successful natural gas hookup requires careful planning between you, your utility company, and a licensed plumber. The utility company (like CenterPoint Energy or National Grid) handles the main gas line to your property and installs the meter. A licensed gas plumber or fitter then runs the lines from the meter to your appliances.

As the homeowner, your key responsibilities include confirming gas availability on your street, securing any necessary building permits, and understanding local codes. Before any digging, you must call 811 or visit 811beforeyoudig.com to prevent damage to underground utility lines.

Also, look for incentives. Many utilities and state programs offer rebates or financial help for switching to natural gas. You may be eligible for federal tax credits on energy-efficient appliances. Some providers, like CenterPoint Energy, may install the first 75 feet of a service line for free when converting a furnace or boiler.

Assessing Your Home’s Gas Capacity

Before adding new gas appliances, you must ensure your system can handle the increased load. First, locate your gas meter and find its capacity rating, typically listed in CFH (cubic feet per hour). Next, list all existing and planned gas appliances and find their BTU (British Thermal Unit) ratings on their labels or in their manuals. Add up the total BTUs. If this total exceeds your meter’s capacity (which can be converted from CFH), your utility company can arrange for a meter upgrade. This check prevents low gas pressure and ensures efficiency. For more help with utility setups, see our utility connection services.

The Process with Your Utility Company

Your utility company will guide you through their specific natural gas hookup process, often detailed on their website, like CenterPoint Energy’s Natural Gas Hook-up in 10 Easy Steps. The process generally starts with submitting a service request form with your property details and desired meter location.

The timeline varies: expect 8-12 weeks if a gas main is on your street, but 16-24 weeks or more if a main extension is needed, especially if road permits are required. That many utilities pause new main installations during winter.

Before work begins, prepare your site by marking all private buried lines (septic, sprinklers) and placing a stake where you want the meter. The utility will then confirm the order, mark their own lines, and install the service line and meter. Costs can vary; for example, CenterPoint Energy may install the first 75 feet of a service line for free for a furnace conversion but charge per foot for additional length. All paperwork and payments are typically required before scheduling.

Special Considerations for Manufactured Homes

At Manufactured Housing Consultants, we understand the unique utility needs of manufactured homes. Many of our new models, like the Bliss TRS14562A or Pride TRU28684R, offer a “Gas Option: Range & Furnace” upgrade (around $1,485.00). This means the home arrives prepped for natural gas with internal piping installed, simplifying the final natural gas hookup.

For existing manufactured homes, upgrading to natural gas may require running new lines, ensuring proper ventilation, and converting appliances from propane. Always use a licensed professional experienced with manufactured homes to ensure the work meets all safety codes.

Proper site preparation is also vital for manufactured homes to ensure all utility connections align correctly. Our team can guide you through this entire process. For more details, see our New Manufactured Home Complete Guide and learn about our Expert Site Preparation and Land Location services.

The Right Stuff: Selecting Pipes and Materials

Choosing the right pipes for your natural gas hookup is critical for safety and longevity. The internal piping must be corrosion-resistant, durable, and correctly sized to deliver adequate gas pressure to all your appliances. The most common materials are black steel pipe, CSST (Corrugated Stainless Steel Tubing), and copper tubing.

Black steel is the traditional, durable choice, while flexible CSST allows for faster installation with fewer joints. Copper is often used for smaller, specific connections. The best material can also depend on local soil conditions, especially for buried lines. Your local building codes will ultimately dictate what is permissible.

Choosing the Right Pipe Material

Each pipe material has distinct advantages for your natural gas hookup.

- Black steel pipe: This rigid pipe is extremely tough and proven for its durability, making it ideal for main runs. However, installation is labor-intensive, requiring threading and more fittings for turns. It must be properly coated if buried to prevent corrosion.

- CSST (Corrugated Stainless Steel Tubing): This flexible tubing can be routed easily through walls and around obstacles in long, continuous runs, reducing potential leak points and installation time. It’s naturally corrosion-resistant but requires special fittings and proper electrical bonding.

- Copper tubing: Flexible and corrosion-resistant, copper is useful for smaller branch lines and appliance connections in tight spaces. However, its use is often restricted by local codes and it requires protection from physical damage.

Always consult a licensed professional and local building codes to ensure you select the correct, safest material for your home.

Sizing Your Gas Pipes Correctly

Correct pipe sizing is essential; pipes that are too small will starve appliances of fuel, while oversized pipes are an unnecessary expense. Sizing for a natural gas hookup depends on several factors:

- Total BTU Load: The combined gas demand of all appliances on a pipe section.

- Pipe Length: Longer runs require larger diameter pipes to maintain pressure.

- Number of Fittings: Each elbow, tee, or valve adds resistance and can necessitate a larger pipe size.

- Gas Pressure: The supply pressure from your utility influences calculations.

Professionals use detailed sizing charts to account for these variables, ensuring every appliance receives the proper gas volume and pressure for safe, efficient operation. For example, a short run to a grill might use 1/2-inch pipe, while a longer run would need 3/4-inch pipe.

The Installation Process: A Step-by-Step Overview

Installing a natural gas hookup is a complex task that is emphatically not a DIY project. Due to extreme safety risks and strict legal codes, you must hire a licensed professional. A qualified gas fitter has the required expertise, tools, and knowledge of local regulations to ensure a safe and compliant installation. In Texas, you can find such professionals through services like Gas Line Install – Pinkys Plumbing Texas. DIY attempts can lead to gas leaks, explosions, voided insurance, and legal penalties.

Safely Disconnecting and Connecting Lines

A professional follows critical safety steps when managing the gas supply:

- Shut Off Main Supply: The main gas valve near the meter is turned off, and all pilot lights are extinguished.

- Release Pressure: Remaining gas pressure in the lines is safely released.

- Tap into Existing Lines: The system is extended by carefully cutting and adding a tee fitting to an existing line.

- Install Shut-Off Valves: A dedicated shut-off valve is installed near each appliance for safety and convenience.

- Use Appliance Connectors: Approved flexible connectors link the rigid pipe to the appliance, allowing for slight movement. A Pipe wrench is used for secure connections.

Ensuring a Secure Natural Gas Hookup

Perfectly sealed joints are non-negotiable for a safe natural gas hookup.

- Seal Connections: All threaded connections are sealed with gas-rated yellow Teflon tape or pipe thread compound, never standard white tape.

- Tighten Fittings: Fittings are tightened securely without over-torquing, often using two wrenches to prevent stress on existing pipes.

- Double-Check Connections: Every joint is visually and physically inspected to ensure a tight fit.

Critical Testing for Your Natural Gas Hookup

Rigorous testing after installation is essential to confirm the system’s integrity.

- Pressure Testing: Before connecting to the main supply, the new line is capped and pressurized. A Pressure gauge is used to ensure the pressure holds steady for a specified time, confirming there are no leaks.

- Manometer Usage: A manometer may be used for precise pressure measurements to ensure appliances operate at their correct water column pressure (WCP).

- Leak Detection Solution: After reintroducing gas, every joint is coated with a soapy water solution. Bubbles indicate a leak that must be fixed immediately.

- Reintroduce Gas Safely: Once all tests pass, the main gas supply is turned on slowly. The area is monitored for the “rotten egg” smell of gas or any hissing sounds.

Common Applications and Considerations

A natural gas hookup provides a convenient, reliable fuel source for many home appliances, including:

- Outdoor grills and indoor fireplaces

- Kitchen ranges and ovens

- Water heaters

- Furnaces and boilers

Once installed, you have a continuous supply of energy without needing to refill propane tanks or worry about running out of fuel.

Hooking Up a Natural Gas BBQ Grill

Connecting your grill to a natural gas hookup eliminates the need for propane tanks. For a safe installation:

- Use quick-connect fittings: The female fitting, which has an auto shut-off safety feature, should be on the house side of the connection.

- Use the correct hose length: Most grills come with a 10-foot hose. Avoid connecting multiple hoses, which can reduce performance and create leak points. Extend the gas line if you need more reach.

- Install safety valves: Have shut-off valves both inside your home and outside near the grill connection.

- Protect exterior pipes: Paint exposed pipes with rust-resistant paint and seal any wall penetrations against moisture.

Always consult your grill’s owner’s guide for specific requirements.

Natural Gas vs. Propane: What’s the Difference?

Natural gas and propane are not interchangeable without modifying the appliance. A natural gas hookup provides fuel differently than a propane tank.

| Feature | Natural Gas (NG) | Propane (LP) |

|---|---|---|

| Pressure | Low pressure (typically 4-7 inches WCP) | High pressure (liquid propane converts to gas) |

| BTU Content | Lower BTU per cubic foot | Higher BTU per cubic foot |

| Port Holes | Larger orifices for burners | Smaller orifices for burners |

| Convenience | Continuous supply, no tank refills | Portable, requires tank refills |

| Cost | Generally cheaper per BTU, especially with a hookup | More expensive per BTU, but tanks are portable |

| Availability | Requires a utility connection | Available via tanks anywhere |

Natural gas operates at a lower pressure and has a lower BTU content than propane. Consequently, natural gas appliances require larger burner orifices to allow sufficient fuel flow. To switch a propane grill to natural gas, you must use a manufacturer-approved conversion kit installed by a qualified professional. Using the wrong fuel type for your appliance is extremely dangerous and can cause it to malfunction or create a safety hazard.

Frequently Asked Questions about Natural Gas Hookups

Here are answers to common questions about getting a natural gas hookup.

Is natural gas line installation a DIY project?

No. Installing a natural gas line is not a DIY project. The risks of gas leaks, explosions, and carbon monoxide poisoning are too high. Gas line installation is governed by strict codes and requires permits. A certified professional has the specialized knowledge and tools to do the job safely and legally. Attempting it yourself can void your home insurance and lead to severe legal and safety consequences. Always hire an expert.

What are the signs of a gas leak and what should I do?

Knowing the signs of a gas leak is critical. The primary indicator is a distinctive “rotten egg” smell, an additive called mercaptan. Other signs include:

- A hissing or whistling sound near a gas line.

- Bubbles in standing water or dead vegetation over a buried line.

- Unexplained headaches, dizziness, or nausea, which can be symptoms of carbon monoxide poisoning.

If you suspect a gas leak, follow these steps immediately:

- Evacuate Immediately: Get everyone out of the house and to a safe distance.

- Do NOT Use Electronics: Do not use light switches, phones, or any appliance that could create a spark.

- Leave Immediately: Do not open windows or try to find the leak. Your priority is to get out.

- Call for Help: Once you are safely away, call 911 and your gas utility’s emergency line.

- Do NOT Re-enter: Wait for emergency personnel to declare the area safe.

What are the typical costs for a natural gas hookup?

The cost of a natural gas hookup varies widely based on several factors:

- Location: Costs differ by region and local utility policies.

- Distance from the Main Line: A longer distance to the gas main increases the cost. Some utilities may offer a free allowance (e.g., the first 75 feet) for certain conversions.

- Appliance Conversions: You may need to buy new gas-compatible appliances or convert existing ones.

- Internal Piping: The length and complexity of the piping inside your home affect labor and material costs.

- Contractor Rates: Get multiple quotes, as plumber rates vary.

- Permit Fees: Municipalities charge for permits and inspections.

- Incentives/Rebates: Ask your utility about programs that can offset costs.

To get an accurate estimate, contact several licensed professionals for detailed quotes. When planning for a new manufactured home, factor these costs into your budget. Our guide on How to Budget for Your New Manufactured Home can help.

Conclusion

A natural gas hookup offers significant energy savings and convenience. The key to a successful project is careful planning with your utility company and hiring licensed professionals for all installation work. For safety reasons, this is never a DIY job.

From calculating your home’s BTU needs and selecting the right pipes to ensuring every connection is pressure-tested, a professional ensures your system is safe and efficient. The long-term benefits, including potential heating cost savings of 30-50% over electricity, make the initial investment worthwhile.

For those buying a new manufactured home in Texas, Manufactured Housing Consultants simplifies the process. Many of our homes come with built-in gas options, such as “Gas Option: Range & Furnace” upgrades, reducing installation complexity.

Our team is here to guide you through every step of setting up your new home, from site prep to the final natural gas hookup. We can help you steer the entire utility connections process to ensure your comfort and peace of mind.