What is Site Preparation and Why it Makes or Breaks Your Project

Site preparation is the essential process of getting your land ready for construction – and it’s arguably the most important phase of any building project. Here’s what you need to know:

Quick Site Preparation Overview:

- Site clearing – Remove trees, vegetation, and debris

- Soil testing – Check load-bearing capacity and drainage

- Grading – Level and slope the land for proper water flow

- Utility trenching – Install water, sewer, and electrical lines

- Foundation prep – Create a stable base for your structure

Think of site preparation as the foundation for your foundation. Without it, even the most beautiful manufactured home can face serious problems down the road.

Why proper site prep matters:

- Prevents costly mistakes – Poor preparation can lead to foundation issues costing tens of thousands to fix

- Ensures safety – Proper grading prevents flooding and structural instability

- Saves time – Good planning prevents delays during construction

- Protects your investment – A well-prepared site means your home will last longer

The research shows that site preparation typically takes 1-2 months for most projects, with costs varying widely based on your land’s condition. For a 2,000 sq ft building, you might spend $250-$600 on clearing, $700-$1,800 on soil testing, and $800-$4,000 on grading.

As one industry expert puts it: “Construction issues are often caused by unexpected ground conditions that could have been avoided if a proper site investigation had been conducted.”

For manufactured homes specifically, site preparation is even more critical. Your home needs a perfectly level, well-drained foundation to prevent settling, cracking, and other structural problems that can be expensive to fix later.

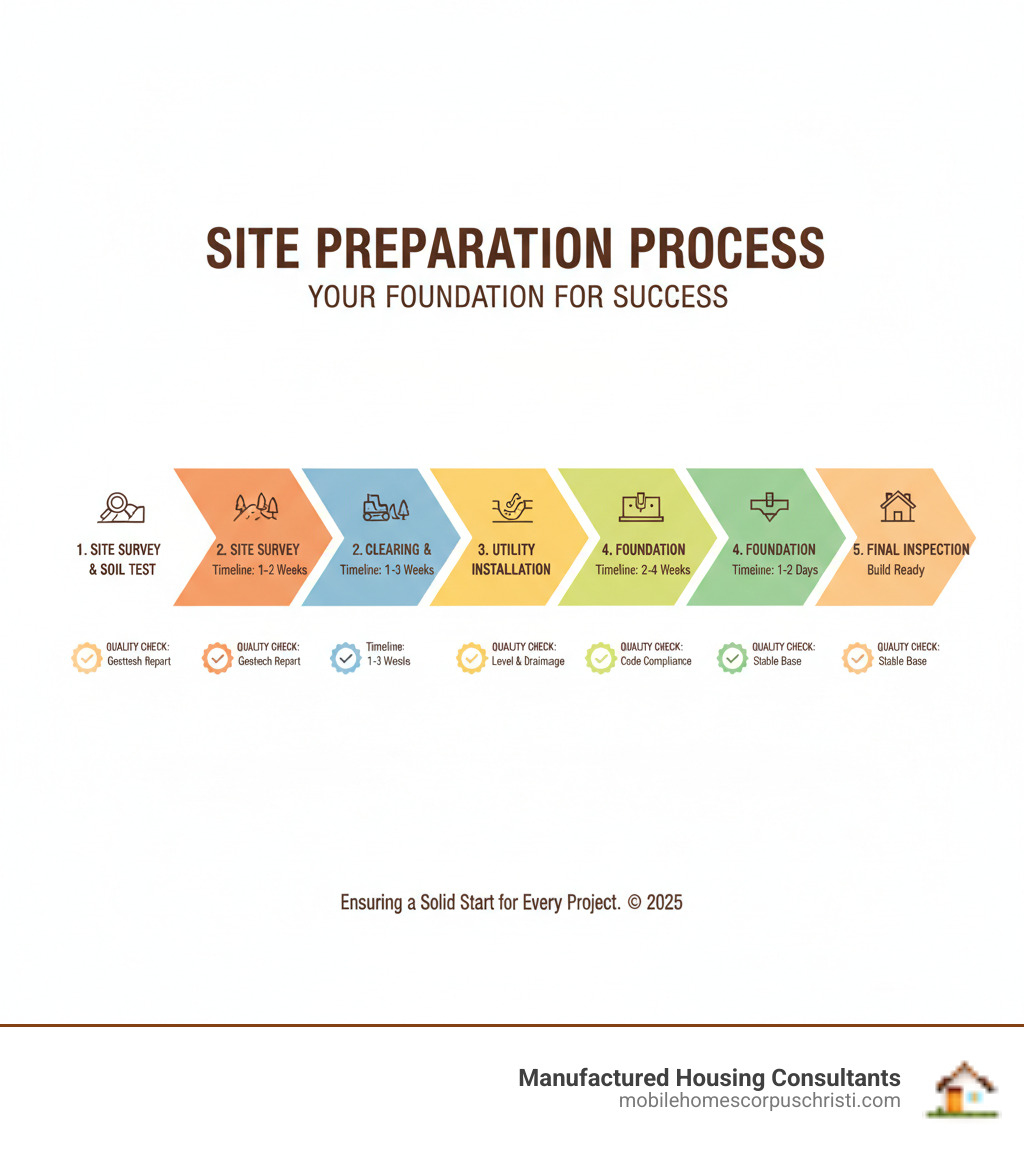

The Step-by-Step Site Preparation Process

Getting your site ready for a new manufactured home isn’t just about moving dirt; it’s a methodical process that requires careful planning and execution. We work with professional contractors who understand the nuances of this critical phase, ensuring every step is handled with precision. From initial assessment to final touches, here’s how we typically approach site preparation.

Site Surveying and Planning

Before any ground is broken, we begin with a comprehensive site survey. This isn’t just a formality; it’s the blueprint for everything that follows. A professional land surveyor will map out your property, identifying precise property lines, potential easements, and existing structures. This crucial step informs us about:

- Property Boundaries and Setbacks: Most localities have strict zoning regulations that dictate how close a structure can be to property lines. For instance, some areas may require a minimum of 5 feet setback from the side or rear property lines. Understanding these rules from the start helps us avoid costly re-dos.

- Easements: Are there any easements on your property for utility lines (overhead or underground) or access roads? We need to know this to plan around them.

- Utility Mapping: Locating existing utility lines and planning for new connections is essential.

- Topography: Understanding the natural contours and slopes of your land helps us design for optimal drainage and home placement.

- Site Plan Design: Based on the survey, a detailed site plan is drafted. This plan outlines the exact placement of your home, access roads, utility connections, and drainage systems, ensuring everything complies with local codes and your vision.

This initial planning phase, including site investigation, is vital for estimating costs accurately and determining the most efficient building methods for your unique property.

Soil Testing and Geotechnical Investigation

Imagine building a castle on quicksand – not a great idea, right? The same principle applies to your manufactured home. The soil beneath your home is its ultimate support system, and understanding its characteristics is non-negotiable.

- Soil Composition: We conduct soil tests to determine what kind of soil you have (clay, sand, loam, etc.) and its classification.

- Load-Bearing Capacity: This tells us how much weight the soil can safely support. This information is critical for designing the right foundation for your home.

- Percolation Tests (Perc Tests): If you’re planning a septic system, a perc test determines how quickly water drains through the soil, ensuring your system will function properly. A county health inspector is usually present to oversee this.

- Identifying Problem Soils: Some soils, like expansive clays, can swell and shrink with moisture changes, potentially causing significant foundation issues. A geotechnical engineer analyzes these physical properties, helping us identify and mitigate such challenges, saving you time and money in the long run. Inadequate soil analysis is a primary cause of site failure.

Our More info about our land location services can help you steer these critical early steps.

Site Clearing and Demolition

With the plans in place and the soil understood, it’s time to prepare the canvas. This phase involves removing anything that shouldn’t be there:

- Vegetation Removal: Trees, shrubs, grass, and stumps all need to be cleared. Depending on the terrain, this might involve extensive tree clearing and root removal.

- Rock and Debris Disposal: Large rocks, construction debris, or other unwanted materials are removed. In areas like Muskoka, with challenging terrain, this can even involve blasting and rock removal, managed with trusted professionals for safety and control.

- Demolishing Existing Structures: If an old building or shed occupies the space, it needs to be safely demolished and the debris hauled away.

- Establishing a Rough Grade: Once cleared, the site is given a preliminary leveling to create a relatively flat surface for the next steps.

This step ensures a clean, unobstructed area for your new home.

Grading, Excavation, and Drainage

This is where the land truly begins to take shape for your home. Grading and excavation are crucial for creating a stable, level pad and ensuring proper water management.

- Leveling the Site: We bring the site to a precise, level grade from which the foundation excavation can proceed. This is particularly important for manufactured homes, which require a perfectly level base.

- Creating Slopes for Drainage: Beyond just leveling, proper grading involves shaping the land to direct water away from your home’s foundation. This prevents water accumulation, which can lead to erosion, foundation instability, and structural damage. Measures like French drains, swales, catch basins, and even retention ponds or silt fences for larger projects, are essential for effective water management and erosion control.

- Foundation Excavation: We excavate the area for your home’s foundation, whether it’s for a slab, runners, or piers.

- Backfilling and Soil Compaction: After excavation, fill soil may be brought in or existing soil redistributed. This soil is then carefully compacted to increase its density and load-bearing capacity, reducing air voids and preventing future settlement. Proper compaction, often to a recommended 1,000 psf or greater, is critical and usually required by building codes to ensure the long-term stability and durability of your home.

Utility Installation

No one wants a beautiful new home without power, water, or a way to manage waste. This step connects your home to the essential services of modern living.

- Trenching for Lines: We excavate trenches for water lines, sewer or septic connections, electrical cables, and sometimes gas lines or communication cables. This requires careful planning to avoid existing underground utilities.

- Coordinating with Utility Companies: We work closely with local utility providers to ensure seamless connections and compliance with their specific guidelines and safety protocols.

- Permitting: Obtaining necessary permits for extending utility lines is a must. A licensed contractor will handle these.

- Temporary Power: If your site doesn’t have existing power, we can arrange for temporary power pole installation. This can cost between $1,700-$4,500. For sites without any power infrastructure nearby, utility costs can range significantly, from $10,000 to over $30,000, depending on proximity to public utility connections.

- Septic System Installation: If your home isn’t connecting to municipal sewer, we’ll oversee the installation of a septic system, guided by the perc test results.

Key Factors Influencing Site Preparation: Scope, Cost, and Timeline

The journey from raw land to a ready-to-build site is highly variable. Several factors play a significant role in determining the scope of work, the overall cost, and the timeline for your site preparation project.

- Project Size: A small shed pad is vastly different from a manufactured home site, which in turn differs from a large commercial project. Larger projects naturally require more extensive work, equipment, and time.

- Location and Terrain: Is your land flat or sloped? Is it heavily wooded or already clear? Are there challenging rock formations or soft, problematic soils? These geographical and geological features directly impact the effort and specialized equipment needed.

- Soil Conditions: As we discussed, the type and stability of your soil can necessitate specific treatments, additional excavation, or specialized fill, all of which add to the complexity and cost.

- Accessibility: How easy is it for heavy machinery and material delivery trucks to access your site? Difficult access can increase labor and equipment costs.

- Weather Impact: Mother Nature can be a fickle friend. Adverse weather conditions like heavy rain can delay work, make soil unstable, and impact schedules, sometimes significantly. Monitoring the forecast is crucial for adapting the construction schedule.

Estimating Costs for Your Project

Site preparation costs are a significant portion of your overall project budget, but they are an investment that pays dividends in longevity and stability. These costs can vary widely based on your specific conditions and the local market in Texas. Here’s a general idea of what to expect for common services:

| Service | Typical Cost Range (2,000 sq ft building) | Typical Cost Range (6,000 sq ft building) | Typical Cost Range (10,000 sq ft building) |

|---|---|---|---|

| Surveying | $200-$2,000 | $200-$2,000 | $200-$2,000 |

| Soil Testing | $700-$1,800 | $700-$1,800 | $700-$1,800 |

| Clearing | $250-$600 | $800-$1,800 | $1,200-$2,800 |

| Site Plan Design | $750-$2,500 | $750-$2,500 | $750-$2,500 |

| Grading | $800-$4,000 | $2,400-$12,000 | $4,000-$20,000 |

Beyond these basic services, remember to factor in:

- Utility Hookup Costs: As mentioned, these can range from $1,700-$4,500 for a temporary power pole to well over $30,000 if your site lacks existing utility infrastructure.

- Permit Fees: These vary by municipality and project scope.

- Unexpected Findies: Hidden rock formations, unforeseen drainage issues, or contaminated soil can add to costs.

For a more comprehensive understanding of the financial aspects, you might want to review How much does it cost to buy & move a mobile home in Corpus Christi?.

Typical Project Timelines

For most build projects, getting the site ready for construction will last between 1 and 2 months. However, several factors can influence this timeline:

- Permit Acquisition: Obtaining necessary permits can take much longer depending on the jurisdiction. This administrative step is often the biggest variable.

- Site Complexity: A heavily wooded or rocky site will naturally take longer to clear than an open field.

- Weather: Persistent rain or extreme temperatures can halt work, especially during excavation and grading phases, extending the timeline.

- Unexpected Ground Conditions: Finding hidden rock formations, unstable soil, or underground water sources can lead to significant delays as new solutions are engineered.

Common Challenges and How to Mitigate Them

Even with the best planning, site preparation can present its share of surprises. Anticipating these challenges and having mitigation strategies in place is key to keeping your project on track.

- Adverse Weather: Heavy rains can turn a construction site into a muddy quagmire, making excavation impossible and compromising soil stability.

- Mitigation: Monitoring weather forecasts, scheduling work during drier seasons, and having temporary drainage solutions or covers ready.

- Hidden Rock Formations: Finding large rocks or bedrock during excavation can slow progress and require specialized equipment like rock hammers or even blasting.

- Mitigation: Thorough geotechnical investigation during the planning phase can identify potential rock issues.

- Poor Soil Quality: Expansive clays, highly organic soils, or unstable fill can lead to foundation problems.

- Mitigation: Detailed soil testing and analysis by geotechnical engineers are crucial. Solutions might include soil stabilization (using additives like lime or cement) or engineering specific foundation designs.

- Permit Delays: Bureaucratic bottlenecks can hold up a project for weeks or even months.

- Mitigation: Starting the permit application process early, ensuring all documentation is complete and accurate, and maintaining open communication with local authorities.

- Environmental Restrictions: Protected wetlands, endangered species habitats, or strict erosion control regulations can impact how and where work can be done.

- Mitigation: Integrating environmental sensitivities into every task from the outset. Conducting environmental impact assessments early and adhering to sustainable practices and regulations.

Proper planning, thorough site investigation, and a flexible approach are our best tools for navigating these potential problems.

Special Considerations for Manufactured Homes

While the general principles of site preparation apply to all construction, manufactured homes have specific requirements that ensure their stability, safety, and longevity. These homes are built with precision in a controlled factory environment and require an equally precise foundation on-site.

What is Included in Site Preparation for a Manufactured Home?

For manufactured homes, the goal is to create a perfectly level, well-drained, and stable pad that supports the entire footprint of the home. This attention to detail is crucial to prevent common issues like settling, uneven floors, or structural stress. Our expert site preparation for manufactured homes typically includes:

- Clearing Organic Material: All topsoil, vegetation, and organic debris are scraped away to prevent decomposition and future settling.

- Creating a Crowned Pad: The site is often “crowned” or slightly mounded in the center, gently sloping outwards. This ensures that water drains away from the home’s perimeter, preventing moisture buildup under the home.

- Gravel Base: A 4″ to 6″ sandy gravel base pad is placed over the prepared site. We use specific sandy gravel materials like Three Quarter Minus, Half Minus, or Sandy Road Base. It’s crucial to avoid gravel with aggregate larger than 3/4″, screened gravel without fines, or “Pit Run,” as these don’t compact effectively.

- Landscape Fabric: Before adding the gravel, a layer of Landscape fabric (also known as weed barrier or stabilization fabric) is laid down. This heavy-duty fabric, similar to what’s used in road construction, prevents weeds from growing through the gravel and helps stabilize the base, preventing the gravel from mixing with the underlying soil.

- Perimeter Requirements: The prepared ground should extend approximately 8 feet larger than the home’s footprint, ensuring ample space for installation and future landscaping. This usually means the gravel pad will be at least 2 feet wider on all sides than the home itself.

- Compaction Standards: The gravel pad is compacted to a recommended 1,000 psf or greater. This ensures a dense, stable base that won’t shift or settle over time.

For a deeper dive into how we tailor our services, check out our Expert Site Preparation and Land Location page.

Foundation and Anchoring

Beyond the pad itself, the foundation and anchoring system are vital for the long-term integrity of your manufactured home. We carefully prepare the site to accommodate the specific foundation type for your home, whether it involves concrete slabs, runners, or piers.

- Frost Protection: In areas with freezing temperatures, we implement measures to prevent frost heave, where freezing and thawing soil can lift and shift foundations.

- Vapor Barriers: As of June 1, 2016, HUD 3285 requires vapor barriers on all new manufactured home sets. These barriers are installed to prevent moisture from rising from the ground and entering the crawl space, protecting the home’s structure and air quality. All vapor barriers must be pulled out past the perimeter of the home.

- Backfill Requirements: For Frost Protected Shallow Foundations, HUD 3285 also requires specific backfill. The perimeter backfill, typically 12″-14″ deep, is sloped away from the home for drainage.

- Proper Anchoring Techniques: Your manufactured home will be securely anchored to the ground, protecting it from high winds and ensuring its stability. We adhere to all HUD/FHA permanent foundation anchoring system requirements.

Our team is well-versed in these specific needs, ensuring your home is installed correctly and safely. Learn more about our comprehensive approach to Manufactured Homes Installation and Delivery.

Frequently Asked Questions about Site Preparation

We understand that site preparation can seem like a complex undertaking, especially if you’re new to the construction process. Here are some of the most common questions we hear, along with our expert answers.

Who is responsible for site preparation?

This is a great question, and the answer can sometimes be a bit nuanced. While the builder is ultimately accountable for the success or failure of the project, they are often “house-centric” – meaning their primary focus is on the construction of the home itself.

For this reason, we often recommend that a dedicated leader or specialist oversees the site preparation phase. This could be the landowner (if they have the expertise), a specialized site preparation contractor, or a project manager. Their role is to:

- Coordinate: Bring together surveyors, geotechnical engineers, utility providers, and excavation teams.

- Plan: Ensure all steps, from soil testing to drainage design, are carefully planned and executed.

- Oversee: Monitor progress, address challenges, and ensure compliance with all regulations.

At Manufactured Housing Consultants, we pride ourselves on guiding you through this process, connecting you with trusted professionals, or managing it directly to ensure your home has the perfect start.

What equipment is used for mechanical site preparation?

The right tools for the job make all the difference! Mechanical site preparation relies on a fleet of heavy machinery designed for efficiency and precision. Here are some of the workhorses you’ll typically see on a site:

- Bulldozers: These powerful machines are perfect for pushing large quantities of soil, clearing land, and establishing rough grades.

- Excavators: With their versatile arms and buckets, excavators are used for digging foundations, trenches, and removing large rocks or stumps.

- Backhoes: A hybrid of a tractor and an excavator, backhoes are excellent for smaller digging tasks and loading materials.

- Graders: These machines feature a long blade used to create a flat surface, spread materials, and establish precise slopes for drainage.

- Soil Compactors (Rollers): Essential for ensuring the stability of the sub-base and fill, compactors use weight and vibration to densify soil, removing air voids and increasing its load-bearing capacity.

- Dump Trucks: For hauling away cleared debris, excess soil, and bringing in fill materials or gravel.

The specific equipment used will depend on the scope of your project and the unique characteristics of your land.

What safety and environmental measures are necessary?

Safety and environmental responsibility are paramount during site preparation. We believe in protecting both our workers and the natural surroundings.

For Safety:

- Personal Protective Equipment (PPE): All personnel on site must wear appropriate PPE, including hard hats, safety glasses, high-visibility vests, and steel-toed boots.

- Site Security and Fencing: The work area is secured with fencing and barriers to prevent unauthorized access and protect the public.

- Clear Signage: Warning signs indicating hazards, restricted areas, and emergency contacts are prominently displayed.

- Safety Protocols and Training: Regular safety briefings, hazard assessments, and ongoing training ensure that everyone understands and follows safe operating procedures.

- Inspections: The site is regularly inspected for potential hazards like exposed wires, uneven surfaces, or unstable structures.

For Environmental Protection:

- Erosion and Sediment Control: Measures like silt fences, sediment ponds, and erosion control blankets are installed to prevent soil runoff into nearby waterways, protecting water quality.

- Dust Management: Watering the site or using dust suppressants helps control airborne dust, improving air quality for workers and nearby communities.

- Protecting Local Ecosystems: We identify and protect sensitive areas like wetlands or protected vegetation. Responsible waste disposal practices are followed to minimize the project’s environmental footprint.

- Sustainable Practices: Where possible, we explore options like reusing excavated soil as fill or recycling cleared materials.

By prioritizing these measures, we ensure that your project proceeds smoothly, safely, and with minimal impact on the environment.

Conclusion: Setting Your Project Up for Success

As we’ve explored, site preparation is far more than just an initial step in construction; it’s the bedrock upon which the success, safety, and longevity of your entire project rests. For manufactured homes, this meticulous attention to detail is especially critical, ensuring that your beautiful new home has the stable, level, and well-drained foundation it needs to stand strong for decades to come.

Ignoring proper site preparation can lead to a cascade of problems, from costly foundation repairs and drainage issues to project delays and safety hazards. But by investing in thorough surveying, soil testing, clearing, grading, and utility installation, you’re not just preparing land – you’re building peace of mind.

At Manufactured Housing Consultants, we understand the unique requirements of manufactured home site preparation here in Texas. Our commitment is to guide you through every phase, ensuring your land is perfectly ready for your new home. We believe that a solid beginning is the best guarantee of a successful and enduring future.

Ready to start your journey with confidence? Check out our New Manufactured Home Complete Guide or Learn more about our professional site preparation services to see how we can help you lay the perfect foundation for your dream home.