Why Proper Ground Preparation Makes or Breaks Your Concrete Project

Preparing land for concrete slab is the foundation of any successful concrete project – whether you’re building a patio, shed base, or preparing for a manufactured home installation. Here’s what the process involves:

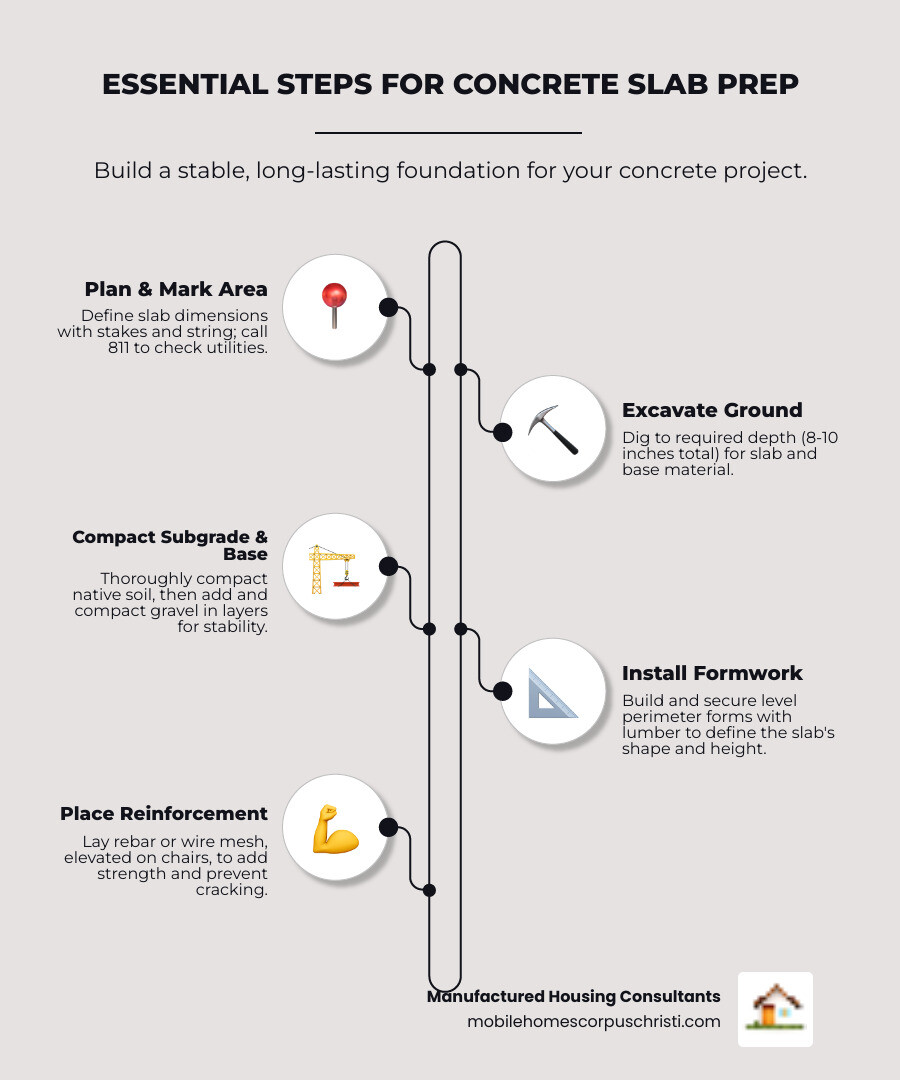

Essential Steps for Land Preparation:

- Plan and mark the area with stakes and string

- Excavate to proper depth (typically 8-10 inches total)

- Compact the native soil to prevent settling

- Add and compact gravel base in 2-inch layers

- Install formwork to define slab boundaries

- Place reinforcement (rebar or wire mesh)

As one concrete expert puts it: “Good finishing techniques will make a slab look great for a while, but proper ground prep will keep it looking that way over its lifetime.”

Why does this matter so much? Skip these steps and you’ll likely see cracks within months. Pour concrete directly on dirt and it will shift and sink. But follow the right process, and your slab can last decades without major issues.

The secret lies in creating uniform support. When one part of your slab settles more than another, it creates stress that leads to cracks. A properly prepared base – with compacted soil and a stable gravel layer – prevents this from happening.

For Texas homeowners, this preparation is especially critical given our clay soils and extreme weather swings. The investment in proper prep work pays off with a foundation that stays level and crack-free for years.

Phase 1: Planning, Tools, and Safety

Success in preparing land for concrete slab starts long before you pick up a shovel. Think of it like cooking a great meal – you wouldn’t start without checking your ingredients and reading the recipe first, right?

Your first decision is site selection. Whether you’re planning a backyard patio, a sturdy shed foundation, or preparing the groundwork for one of our beautiful new homes in Texas, location matters more than you might think. You’ll want to consider drainage patterns, sun exposure, and accessibility for concrete trucks.

Here’s something that could save you thousands of dollars and a lot of trouble: Call 811 before you dig! This free service marks underground utilities like gas lines, water pipes, and electrical cables. Trust me, accidentally hitting a gas line with your shovel is not the kind of excitement you want in your life.

Understanding local Texas building codes is your next homework assignment. These aren’t just bureaucratic hoops to jump through – they’re designed to keep your project safe and structurally sound. Building codes dictate everything from how thick your slab needs to be to what kind of reinforcement you’ll need.

Now let’s talk about something uniquely Texan – our challenging soil conditions. Here in the Corpus Christi area, we often deal with clay soils that love to play tricks on concrete slabs. Clay expands when it gets wet and shrinks when it dries out, which can spell disaster for an unprepared foundation. Sandy soils, on the other hand, are much more cooperative – they compact well and drain nicely. Knowing what you’re working with helps determine how deep you’ll need to dig and what kind of base material you’ll need. For detailed guidance on site assessment and soil evaluation, check out our expertise in land location.

Texas weather deserves its own planning consideration. Our scorching summers can make concrete cure too quickly, leading to cracks. Heavy rainstorms can turn your perfectly prepared work site into a muddy disaster. The sweet spot for concrete work is typically between 40°F and 85°F with dry conditions – which makes spring and fall your best friends for this kind of project.

Tools and Materials You’ll Need

Having the right tools makes the difference between a weekend warrior success story and a cautionary tale. Here’s what you’ll need to get the job done right:

For site clearing and excavation, you’ll want the basics: a good shovel for digging, a rake for smoothing, and a wheelbarrow for hauling dirt and gravel around. A tape measure and string line with stakes are essential for marking your area precisely – eyeballing it just doesn’t cut it for concrete work.

Leveling and compacting tools are where things get more serious. A long level or laser level ensures everything is perfectly flat (or properly sloped for drainage). For smaller areas, a hand tamper will do the job, but for anything larger than a small patio, invest in a vibratory plate compactor. This machine uses vibration to pack soil and gravel much more effectively than you could ever achieve by hand.

Base materials and formwork include crushed gravel or stone for your subbase, lumber (2x4s or 2x6s) for creating the concrete’s boundaries, and screws with a drill to secure everything. Screws hold much better than nails and won’t work loose when the concrete truck shows up.

Reinforcement materials are crucial for a strong slab. You’ll need either rebar or wire mesh to prevent cracking, plus rebar chairs to keep that reinforcement properly positioned. These little plastic or metal supports ensure your rebar stays centered in the concrete instead of lying uselessly on the ground. Don’t forget rebar ties and a tying tool to secure everything together.

The key is having everything ready before you start. Once you begin preparing land for concrete slab, momentum is important – you don’t want to stop halfway through because you’re missing a crucial tool or material.

Phase 2: The Step-by-Step Guide to Preparing Land for Concrete Slab

Now we get to the fun part – actually preparing land for concrete slab! Think of this phase as building the invisible foundation that’ll keep your concrete looking perfect for decades. Whether you’re creating a cozy patio or laying the groundwork for a manufactured home installation, these six steps are your roadmap to success.

Step 1: Mark and Clear the Area

Picture this: you’re an artist about to create a masterpiece, but first you need to prep your canvas. That’s exactly what we’re doing here – creating clean boundaries for our concrete masterpiece.

Start by marking your slab dimensions using stakes and string line. Drive those stakes about a foot beyond each corner of your planned slab, then stretch mason’s string tight between them. This string should sit right at the height where you want your finished concrete surface.

Here’s where that old carpenter’s trick comes in handy – the 3-4-5 method for square corners. Measure 3 feet along one string from any corner, then 4 feet along the connecting string from that same corner. If the distance between these two points measures exactly 5 feet, congratulations! Your corner is perfectly square. If not, adjust your stakes until it is.

Clearing comes next, and this is where we get serious about removing everything. Grass, weeds, roots, rocks, that old garden gnome your neighbor’s been complaining about – it all has to go. Any organic matter left behind will decompose over time, creating little pockets that’ll cause your concrete to settle unevenly. Trust us, spending extra time here saves headaches later.

Step 2: Excavate the Ground to the Proper Depth

Time to dig! But before you start channeling your inner construction worker, let’s talk numbers. Determining the right excavation depth is like following a recipe – get it wrong and the whole thing falls apart.

For most home projects, we follow the general rule of 8-10 inches total depth. This breaks down to about 4 inches for your concrete slab plus 4-6 inches for the gravel base underneath. Think of it as building a layer cake – each layer has its purpose.

Digging out the marked area is straightforward but requires patience. Remove all soil down to your calculated depth, and keep an eye out for any surprise visitors – large rocks, stubborn roots, or old utilities that weren’t marked properly. Remove these obstacles as you encounter them.

The goal is getting your excavated base relatively flat and level. It doesn’t need to be perfect at this stage, but the closer you get now, the easier your life becomes in the next steps.

Step 3: Compact the Native Soil (Subgrade)

Here’s where many DIY projects go wrong – they skip this step entirely. Don’t be that person! Compacting the subgrade is absolutely crucial because loose soil is concrete’s worst enemy.

Think about it this way: if you pour concrete over fluffy, uncompacted dirt, what happens when that dirt decides to settle? Your beautiful slab develops cracks, dips, and all sorts of expensive problems. Proper compaction prevents future settling by squeezing out air pockets and creating a rock-solid foundation.

For small areas, use a hand tamper – it’s like a giant stamp that you lift and drop repeatedly. For larger slabs, rent a plate compactor – these vibrating machines do the heavy lifting for you and create much better results.

Here’s a pro tip: dampen the soil slightly before compacting. Grab a handful and squeeze it – if it holds together like Play-Doh, you’re golden. If it crumbles, sprinkle some water. If it’s muddy, wait for it to dry a bit.

Keep working until the surface feels firm and unyielding under your feet. When you can walk across it without leaving deep footprints, you’ve achieved victory.

Step 4: Add and Compact the Subbase

Now for the unsung hero of concrete work – the gravel subbase. This layer is like the shock absorber in your car: you don’t see it working, but without it, everything falls apart.

The subbase serves double duty – it provides drainage so water doesn’t pool under your slab, and it spreads the weight of your concrete evenly across the ground below. Think of it as insurance against settling and cracking.

Use crushed gravel or stone – not the pretty river rock from your garden center, but the angular stuff that locks together when compacted. For most patios and walkways, 4-6 inches thick works perfectly. If you’re building something that’ll support heavier loads, bump that up to 6-8 inches.

Here’s the secret: spread gravel in 2-inch layers and compact each one separately. Dump all 6 inches at once and try to compact it? You’ll get a nicely compacted top inch sitting on 5 inches of loose gravel underneath.

Compact each layer thoroughly with your plate compactor, making several passes until the gravel stops moving under the machine. You’ll actually hear the difference – loose gravel sounds crunchy, while properly compacted gravel has a solid, dense sound.

Step 5: Install the Formwork

Time to build the frame that’ll hold your concrete in perfect shape. Forms define your slab’s final height and shape, so accuracy here directly translates to a professional-looking finished product.

Build your perimeter frame with lumber – typically 2x4s for a 4-inch slab or 2x6s for thicker concrete. These boards create the mold that contains your concrete during the pour.

Secure forms with stakes driven into the ground every 2-3 feet along the outside of your boards. Use screws rather than nails – they hold much better when hundreds of pounds of concrete start pushing against your forms.

Double-check that forms are level and square using your longest level and that trusty 3-4-5 triangle method again. If your slab will be next to a building, create a slight slope for drainage – about 1/8 inch per foot away from the structure. This tiny slope prevents water from pooling against foundations and causing expensive damage later.

Step 6: Place Reinforcement

Last step before the concrete arrives! Reinforcement is important for strength because while concrete handles compression wonderfully, it’s not great at resisting tension – the forces that try to pull it apart.

Steel rebar or wire mesh prevents cracking under load from settling, temperature changes, or heavy objects. For most home projects, welded wire mesh works great for patios and walkways, while rebar in a grid pattern is better for driveways or areas supporting heavier structures.

Here’s the critical part that many people mess up: lift reinforcement off the subbase with chairs. Those little plastic or metal supports aren’t optional – they’re essential. Rebar sitting on the ground does absolutely nothing to strengthen your concrete. It needs to be suspended in the middle to upper portion of your slab to work properly.

Tie rebar intersections with wire ties to keep everything in position during the concrete pour. Take your time with this step – properly placed reinforcement is the difference between a slab that lasts decades and one that starts cracking within months.

With your reinforcement in place and properly supported, you’re ready for the concrete pour. All this careful preparation creates the invisible foundation that’ll keep your project looking perfect for years to come.

Common Mistakes and Best Practices

Even with the best intentions, mistakes can happen. But when preparing land for concrete slab, these errors can be costly, leading to a cracked, sunken, or unstable slab. Let’s review how to avoid them and ensure a flawless foundation.

Best Practices for a Flawless Foundation

We want your concrete slab to stand the test of time, just like our manufactured homes are built to last. Here are our best tips:

- Uniform Support is Key: As we’ve emphasized, the most critical factor is ensuring the entire area beneath your slab has consistent support. Any soft spots or uncompacted areas will inevitably lead to settlement and cracking.

- Double-Check Everything: Measure twice, cut once – and compact twice, check level twice! Take your time with each step, especially marking, excavation depth, and formwork leveling.

- Use High-Quality Base Materials: Don’t skimp on the gravel or crushed stone. Good quality, angular aggregate compacts better and provides superior drainage and stability.

- Don’t Skip Compaction on Any Layer: Every layer, from the native subgrade to each lift of gravel, needs thorough compaction. This is the backbone of your slab’s stability.

- Consider a Vapor Barrier for Interior Slabs: For any interior concrete slab (like a garage floor or a slab that will be covered with flooring), installing a vapor barrier (heavy-duty plastic sheeting) over the compacted subbase is a smart move. This prevents moisture from the ground from migrating up through the concrete, which can cause issues with flooring or create dampness.

- For a deeper dive into the science behind what lies beneath, explore these expert tips on subgrades and subbases.

Common Mistakes When Preparing Land for a Concrete Slab

Knowing what not to do is just as important as knowing what to do. Here are the most common pitfalls we see:

- Inadequate Excavation Depth: Not digging deep enough means you won’t have sufficient space for both your concrete and a proper subbase. This leads to a thin, weak slab or poor drainage.

- Pouring on Uncompacted or Organic Soil: This is a recipe for disaster. Uncompacted soil will settle unevenly, and organic matter (like grass or roots) will decompose, creating voids. Both lead to cracks and sinking.

- Forgetting to Slope for Drainage: A flat slab, especially outdoors, will collect water. This can lead to erosion, freeze-thaw damage, and even foundation issues for adjacent structures.

- Incorrect Formwork Setup: Forms that aren’t level, square, or securely braced will result in a crooked or misshapen slab. They can also bow or break during the pour.

- Letting Rebar Lie on the Ground: Reinforcement needs to be suspended within the concrete to be effective. If it’s resting on the subbase, it’s doing very little to prevent cracking.

- Ignoring Weather Conditions: Pouring concrete in extreme heat (causing it to dry too fast) or heavy rain (adding too much water to the mix and subgrade) can severely compromise the slab’s strength and durability.

Frequently Asked Questions about Slab Preparation

Over our years helping Texas homeowners with foundation projects, we get the same questions about preparing land for concrete slab time and time again. And honestly, we love these questions! They show you’re thinking ahead and want to do things right the first time. Let’s explore the most common ones.

Can you pour concrete directly on dirt?

Here’s the short answer: technically you can, but you absolutely shouldn’t. We’ve seen too many DIY disasters where someone thought they could skip the prep work and just dump concrete straight onto the ground.

Think about what dirt really is. It’s full of organic matter that will decompose over time, creating little pockets and voids under your slab. It has varying moisture levels that cause it to expand and contract. And it’s just naturally inconsistent – some spots are denser than others.

When you pour that heavy concrete on top, physics takes over. The dirt shifts, settles, and compacts unevenly. What starts as a beautiful, smooth slab turns into a cracked, sunken mess within months. We’ve had homeowners call us in tears because their “simple weekend project” turned into a costly repair job.

A compacted gravel subbase provides the stability and drainage that bare dirt simply can’t offer. It’s like the difference between building a house on quicksand versus bedrock. The extra work upfront saves you headaches (and money) down the road.

How thick should the gravel base be for a concrete slab?

This is where the “it depends” answer comes in, but don’t worry – we’ll break it down so it makes perfect sense.

For patios, walkways, and shed bases – basically anything that won’t see heavy traffic – a 4-inch thick gravel base is your sweet spot. This gives you solid drainage and plenty of support for normal use.

When we’re talking about driveways or garage floors where cars will be parked, we bump that up to 6-8 inches. Those extra inches make a huge difference when you’ve got a pickup truck sitting on your slab day after day.

Here in Texas, especially with our clay soils that love to expand and shrink with moisture changes, we sometimes go even thicker. If you’re dealing with particularly challenging soil conditions, 8-10 inches isn’t overkill – it’s smart planning.

This gravel needs to go down in thin layers. Don’t just dump 6 inches of gravel and call it good. Spread it in 2-inch lifts and compact each layer thoroughly. This creates that rock-solid foundation your concrete needs.

Why is compacting the soil so important?

This might be the most important question of all, because skipping compaction is the number one reason slabs fail.

Picture this: you’re building a sandcastle, and you just pile up loose sand versus packing it down tight. Which one holds its shape better? The packed sand, every time. The same principle applies to preparing land for concrete slab.

Uncompacted soil is full of air pockets. When you pour thousands of pounds of concrete on top, those air pockets gradually collapse. But they don’t collapse evenly – some areas settle more than others. This creates stress in your concrete, and stress leads to cracks.

Compaction also removes organic matter and increases the soil’s density. Dense soil has a much higher bearing capacity, meaning it can support more weight without shifting or deforming. Think of it as creating a solid, predictable platform for your concrete.

The magic happens when you achieve uniform support across the entire area. Every square foot of your slab sits on equally stable ground. No weak spots, no surprise settlements, no differential movement that causes those zigzag cracks we’ve all seen in poorly prepared slabs.

For larger projects, like the foundation prep for our manufactured home installations, proper compaction isn’t just recommended – it’s absolutely critical. A home foundation that settles unevenly can cause structural issues that are expensive and difficult to fix.

The bottom line? Those few extra passes with the compactor today prevent years of problems tomorrow. It’s one of those investments that pays for itself many times over.

Your Foundation for Success

After walking through all these steps together, I hope you can see why preparing land for concrete slab is truly the make-or-break moment for any concrete project. It’s not just about creating a pretty surface – though that’s nice too! – it’s about building something that will stand strong for decades without giving you headaches.

Think of it this way: you can have the most skilled concrete finisher in Texas, but if the ground underneath isn’t properly prepared, that beautiful smooth surface will crack and sink within a year or two. On the flip side, even a basic concrete pour over a perfectly prepared base will outlast and outperform expensive concrete poured on shortcuts.

The beauty of proper ground preparation is that it prevents all the problems we hate to see: cracks that spider across your patio, low spots that collect rainwater, and uneven settling that makes your shed door stick. When you invest the time upfront to compact that subgrade, add the right gravel base, and get everything level, you’re essentially buying yourself years of worry-free enjoyment.

Now, let’s be honest – while many of these steps are totally doable for a weekend warrior with some determination, bigger projects can get complicated fast. If you’re dealing with tricky clay soil, a large foundation, or the critical base for a new manufactured home, that’s when professional expertise really pays off. There’s something to be said for having experienced hands handle the foundation that your entire home will sit on.

Here in the Corpus Christi area, we’ve seen how proper site preparation makes all the difference. At Manufactured Housing Consultants, we know that your beautiful new home deserves the most solid start possible. That’s exactly why we offer comprehensive Expert Site Preparation services – because we believe every home should start on rock-solid ground.

Whether you’re planning a DIY patio project or need professional foundation work for your new manufactured home, everything starts with that first step of proper ground preparation. Get that right, and you’re setting yourself up for success that will last for years to come.